Stocklist - Thermoforming machines

Last update: 19.11.2019

VM 042: RDK 80 k

Illig automatic pressure forming machine RDK 80 k,

basic machine with following equipment:

|

|

Illig material roll stand, type ROK 800 |

|

|

1 set clamping cones for reel cores with inside diameter of 70 - 95 mm |

|

|

pneumatic reel loading device |

|

|

Illig roll pre-heater, type VHW 90/2b |

|

|

field bus connection |

|

|

air conditioner for control cabinet |

|

|

adapter for stand to position VHW |

|

|

Illig RDK 80 k with |

|

|

ThermoLineControl |

|

|

start-up operation with reduced number of cycles |

|

|

heater-compensation: improvement of repeatability of heating |

|

|

dynamic process optimization for speeds up to 55 cycles |

|

|

field-bus interlinkage for material roll stand ROK 800 and VHW 90/2b |

|

|

cross adjustment of material web |

|

|

automatic lubrication for material transport chains |

|

|

upper and lower heater with longitudinal row control, 4 rows of short heater elements each (122 x 60) can be switched off on feed side to adapt length to heating area |

|

|

upper and lower heater with HTSs heater elements |

|

|

heater covers, water-cooled, with parking position |

|

|

spreading device, servo-driven, additionally in front of forming station |

|

|

servo-drive for upper clamping frame and pre-stretcher |

|

|

separate tool cooling on forming station |

|

|

blowing-out device, manually, for tool cooling water |

|

|

actuation for A/B stacking in forming tool |

|

|

print mark registration control in center of forming tool |

|

|

device for tool change on thermoforming station |

|

|

stacking station with counting and push-out device |

|

|

servo-drive for clamping, break-out and push-out movement in operating direction |

|

|

discharge conveyor with 2550 mm length |

|

|

air conditioner for control cabinet |

|

|

skeletal rewinding device with pneumatic roll push-out unit |

|

|

C.M.G. skeletal web granulator, type NT35120RSE |

|

|

feed chute for forming parts |

|

|

C.M.G. conveyor for remaining material |

|

|

M/C auto sealing machine (year of construction: 2012) with |

|

|

M/C shrink oven tunnel (year of construction: 2015) |

Year of construction: 2014

Working hours: 3.000

Price: on request, in Germany additional VAT, FCA, subject to prior sale

The machine can be watched after agreement of date.

Technical modifications reserved.

|

||||||||||||||

|

|

|

|

|

|

|

|

|||||||

|

||

|

|

|

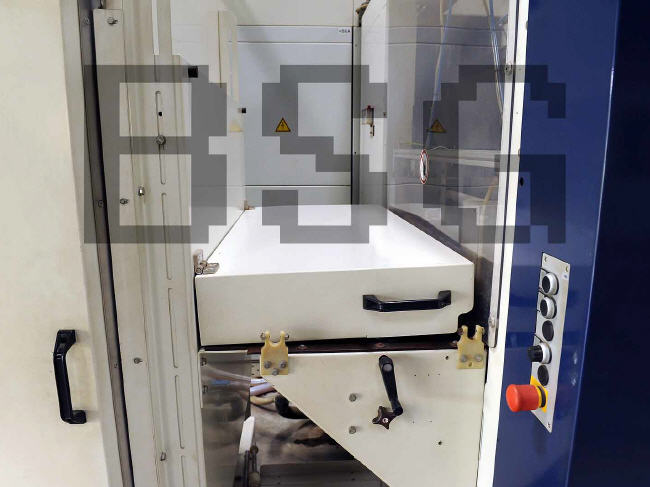

VM 043: RDK 80 k

Illig automatic pressure forming machine RDK 80 k,

Basic machine with following equipment:

|

|

Illig material roll stand, type ROK 800 |

|

|

1 set clamping cones for reel cores with inside diameter of 70 - 95 mm |

|

|

pneumatic reel loading device |

|

|

Illig roll pre-heater, type VHW 90/2b |

|

|

field bus connection |

|

|

air conditioner for control cabinet |

|

|

adapter for stand to position VHW |

|

|

Illig RDK 80 k with |

|

|

ThermoLineControl |

|

|

start-up operation with reduced number of cycles |

|

|

heater-compensation: improvement of repeatability of heating |

|

|

dynamic process optimization for speeds up to 55 cycles |

|

|

field-bus interlinkage for material roll stand ROK 800 and VHW 90/2b |

|

|

cross adjustment of material web |

|

|

automatic lubrication for material transport chains |

|

|

upper and lower heater with longitudinal row control, 4 rows of short heater elements each (122 x 60) can be switched off on feed side to adapt length to heating area |

|

|

upper and lower heater with HTSs heater elements |

|

|

heater covers, water-cooled, with parking position |

|

|

spreading device, servo-driven, additionally in front of forming station |

|

|

servo-drive for upper clamping frame and pre-stretcher |

|

|

separate tool cooling on forming station |

|

|

blowing-out device, manually, for tool cooling water |

|

|

actuation for A/B stacking in forming tool |

|

|

print mark registration control in center of forming tool |

|

|

device for tool change on thermoforming station |

|

|

stacking station with counting and push-out device |

|

|

servo-drive for clamping, break-out and push-out movement in operating direction |

|

|

discharge conveyor with 2550 mm length |

|

|

air conditioner for control cabinet |

|

|

skeletal rewinding device with pneumatic roll push-out unit |

|

|

C.M.G. skeletal web granulator, type NT35120RSE |

|

|

feed chute for forming parts |

|

|

C.M.G. conveyor for remaining material |

|

|

M/C auto sealing machine (year of construction: 2012) with |

|

|

M/C shrink oven tunnel (year of construction: 2015) |

Year of construction: 2014

Working hours: 2.500

Price: on request, in Germany additional VAT, FCA, subject to prior sale

The machine can be watched after agreement of date.

Technical modifications reserved.

|

||||||||||

|

|

|

|

|

|

|||||

|

||||

|

|

|

||

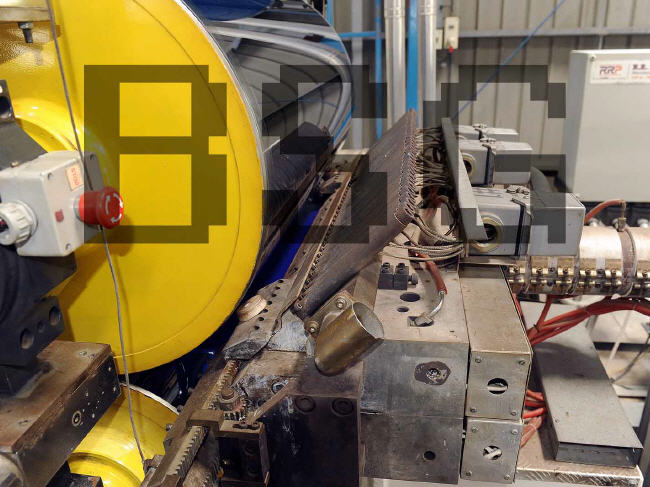

VM 044: RRP extrusion line for PP mono layer

Model: RRSL 150/33 (1000 mm) SP series sheet line plant

Material: PP/HIPS (thermoforming grade)

Thickness: 0.4 mm to 2.5 mm (thickness variation less than ± 3%)

Sheet width: 850mm (after trim)

Sheet output: 750 – 800 kg/hr for PP, 900 – 1000 kg/hr for HIPS

Screw material: Bimetallic

Barrel material: Bimetallic (X-ALLOY, USA)

Screw dia.: 150 mm

L/D Ratio: 33:1

Main Drive: 200 kW AC heavy duty Motor [Make-Siemens]

with AC frequency variable drive [Make – A.B.B.]

Extrusion line with following equipment:

Screen changer: Hydraulic dual plunger continuous type [RRSC/HDPLUC – 120]

Melt pump: RRMP/EX – 70 (Make – MAAG - Switzerland)

Static mixture: [RRSM – 3 – 6]

Sheet die: [RRDH/I – 1000] (coat hanger type)

EDI auto flex Die (made in China) model: - VIII LH 100 die 1000

Vertical calender unit: [RRCAL/SPV – 400/600/600 x 1000] with servo drive

Thermoregulation unit: [RRTRU/W – 7]

Thickness measure gauge: Laser

Dual edge trim grinder: [RRETG – 300] with auto feedback

Edge trim winder: [Make Bonfiglioli, Italy]

Nip roll unit: [RRNU/SP – 1000]

Static eliminato: [RRSE - 1000]

Two station jumbo winder: [RRWU/J2 – 1000] [Make – Bonfiglioli, Italy]

driven by AC frequency variable drive, Maximum dia.: 1200mm

Year of construction: 2015

Working hours: 6.000

Price: on request, in Germany additional VAT, FCA, subject to prior sale

The machine can be watched after agreement of date.

Technical modifications reserved.

|

||||||||||||||

|

|

|

|

|

|

|

|

|||||||

|

||||||||

|

|

|

|

|

||||

|

||

|

|

|

(C) 2009 Becker Service GmbH - All rights reserved.